Boost productivity with real-time equipment insights and streamlined operations

Advantech WISE-IoT Machine Inspector is designed to collect real-time equipment data, ensuring swift notification of personnel for timely handling. It also simplifies coordination for reserving spare parts, effectively reducing downtime and enhancing equipment productivity. By doing so, it mitigates capacity waste and optimizes operational efficiency.

Effortless Anomaly Detection and Equipment Maintenance with Machine Inspector

Adopting Benefits

Reduce Unscheduled Downtime

- Real-time monitoring of equipment and production via mobile notifications help quickly address abnormal events.

Return on Investment

- Pre-defined equipment maintenance key performance indicators help to review the current maintenance policy for correctness.

Spare Parts Cost Control

- Combine maintenance work orders to understand past maintenance costs and assist in evaluating future spare part requirements.

Feature Highlights

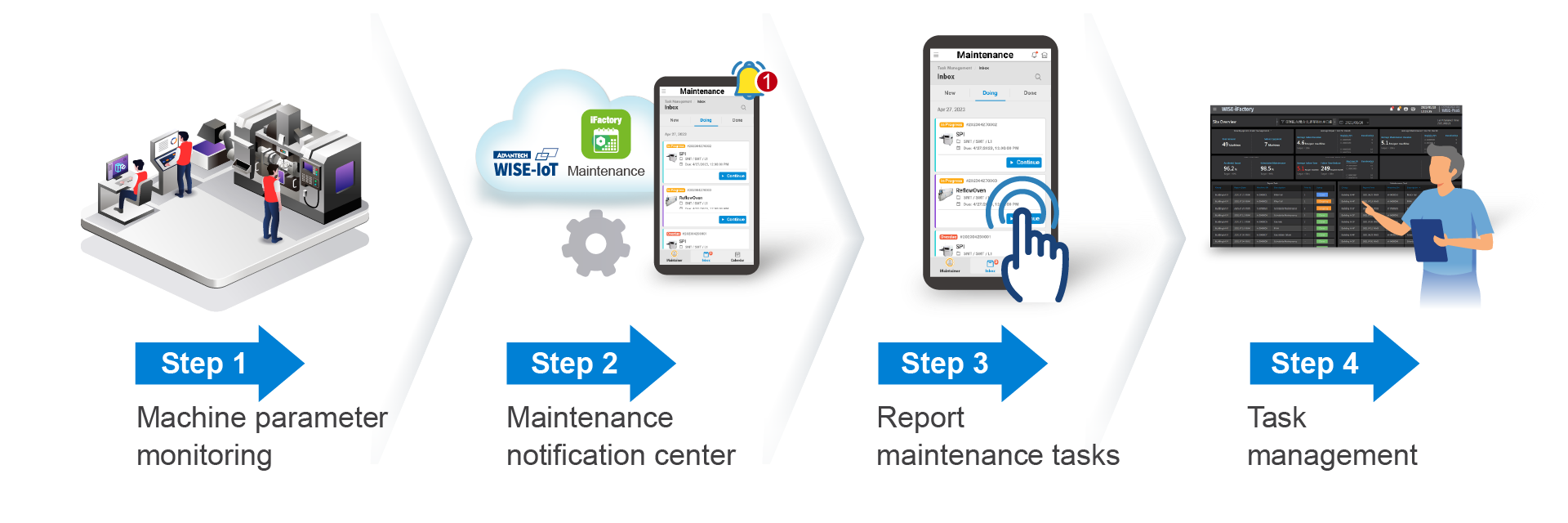

Automated Requests

- Automatically generates maintenance tasks through monitoring of indicator parameters.

KPI Dashboard

- Calculate MTBF, MTTR, and other equipment maintenance indicators using existing maintenance work order data.

Spare Parts Management

- Well-documented spare parts inventory assists maintenance personnel ensure timely completion of work.

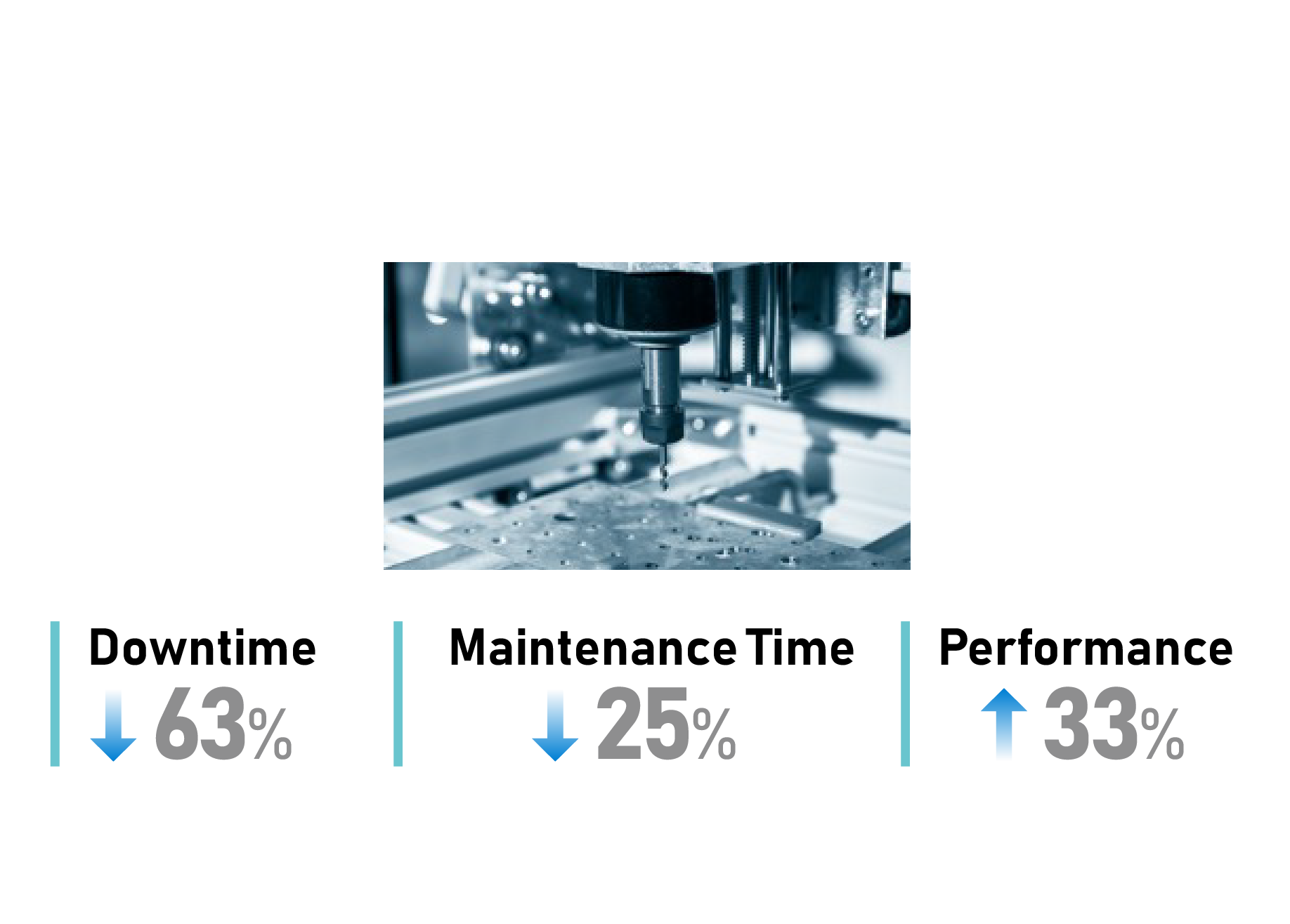

Improve Productivity in CNC Machine Parts Manufacturing

A metal manufacturing company lacked systematic maintenance equipment policies, causing frequent defects and delays in addressing issues, resulting in decreased production output. Advantech's affordable Machine Inspector starter package minimizes downtime and enables proactive maintenance.

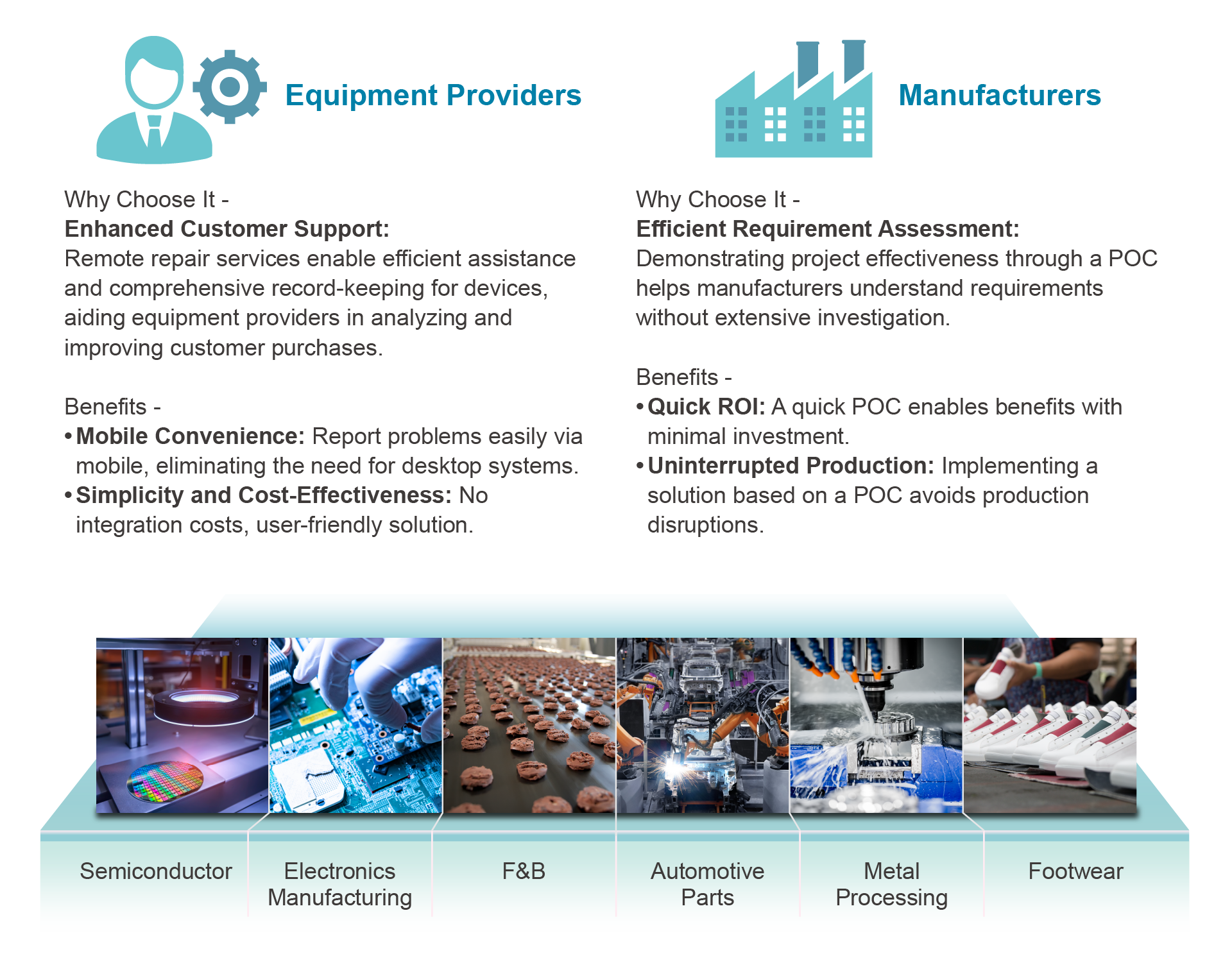

Design for Equipment Providers and Manufacturers

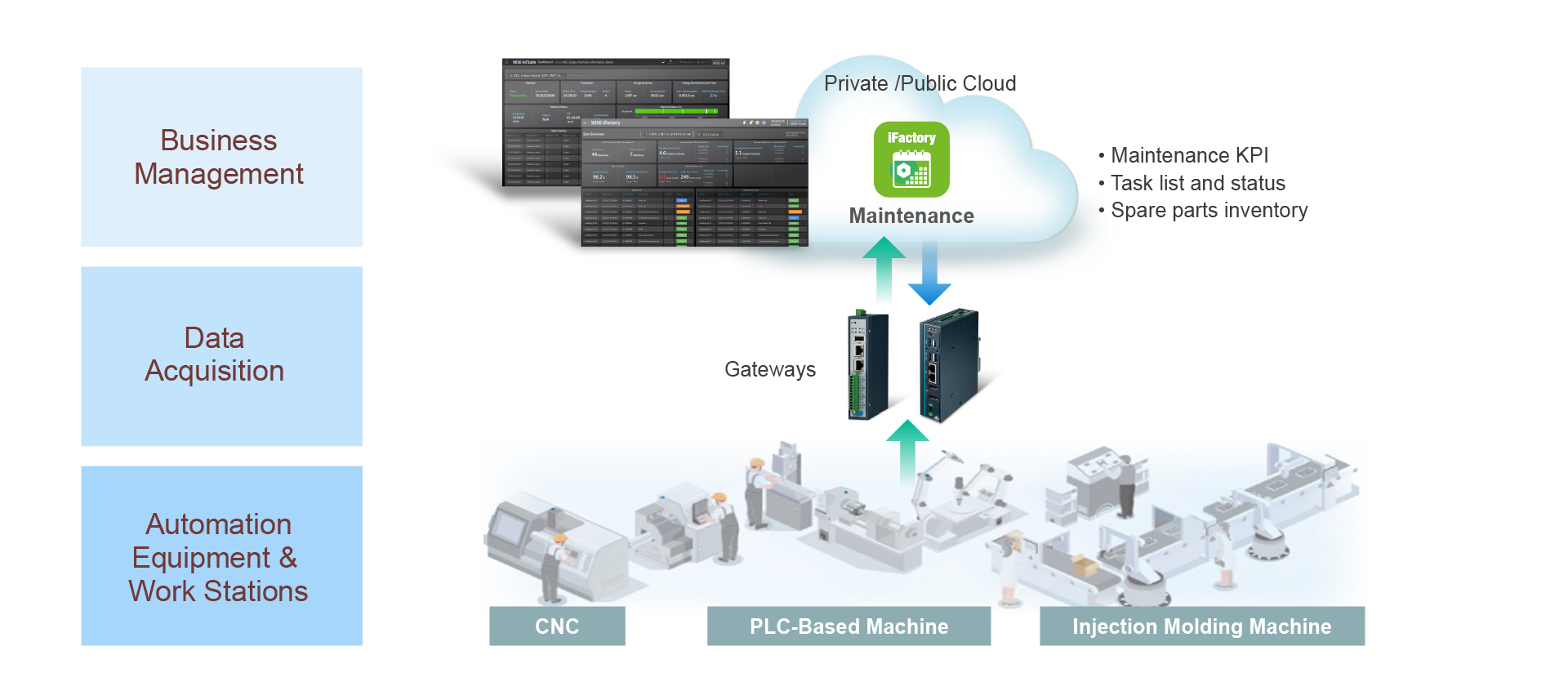

Machine Inspector - System Diagram

Intelligent Software Suite for the Machine Inspector Starter Package

Industrial Apps

Maintenance App

- The Maintenance App provides an easy-to-use tool to speed up the visualization of all machine status and health conditions, which reduces unplanned downtime and equipment failures.

Edge Devices

Computing & Protocol Gateway Packages

Computing & Protocol Gateway PackagesAdvantech offers a multitude of computing platforms to fit different edge computing needs. There is also an add-on protocol suite that collects data from different controller brands while still remaining a programmable edge platform.

Edge Solution

Edge SolutionHigh-performance, ready-to-run data acquisition, dashboard, and preinstalled software for real-time monitoring.