WISE-AIFS Smart Manufacturing AI Industrialization Platform

Assist modern factories to build exclusive AI applications with self-developed and cooperatively-developed industrial solutions. Complete the first mile of business value conversion!

Do You Know?

Only 53% AI projects can be transformed from AI prototypes into usable production tools.

STAMFORD, Conn., October 19, 2020

- 01

AI project development is not fast enough

The shortage of professional talents makes it difficult for companies to achieve their goals in the digital transformation process. Project development is often time-stressed. If the end-users' expected results are not provided, important customers may not only be lost, but also wasted development time and labor cost.

- 02

Welcome to the No-Code era

The trend of civilianization of AI modeling has arrived. Engineers need to focus more on improving their professional background in specific fields. For example, 'Let machines judge defective products' is the most common application of smart factories, but how to teach machines to define defects is the core issue.

WISE-AIFS AI Industrialization Platform

MLOps one-stop AI industrialization application development platform | Assist industrial customers to complete the AI import production management process | Explore the infinite possibilities of Industry 5.0 intelligent automation!

Explore the WISE-AIFS : AI Industrialization Platform

Why WISE-AIFS?

No-Code AI

Provide AI automatic learning service (AutoML), so that users with data can quickly model and go online without developing code.

AI modeling is fast

Simplify the workflow of AI modeling, and provide tools that facilitate data processing, batch modeling, and batch remote deployment online.

Convenient model deployment

Provide remote model development, users can remotely deploy to Windows, Linux, Docker, and EdgeX Foundry devices.

Easy to mark and clean data

The end-user-friendly operation interface quickly displays the effectiveness of the model and provides labeling tools to speed up the process efficiency of expert labeling and driving the model in training and automatic optimization.

AI model retraining is easy

Fully automatic model training and deployment, retraining and redeployment are all driven by the task scheduler.

AI platform is easy to operate and maintain

Pool massive computing resources and provide services to maximize computing resource utilization and manage gaps to improve the operating efficiency of the AI platform.

4 major services

AIFS/Resource Management

- Resource Management

- AIFS/Resource Management

- Computing resource cluster configuration

- Computing resource monitoring

AIFS/Development Service

- AI development service tools

- AIFS/Development Service

- Model development and version management

- Model retraining and deployment management

AIFS/AutoML

- No-code modeling tool

- AIFS/AutoML

- Structured data classification and prediction

- Image classification, object detection

AIFS/Evolution

- Automatic auxiliary marking tool

- AIFS/Evolution

- AI assisted marking tool

- Mark project and history management

AIFS/PHM (Prognostics and Health Management)

For zero-tolerance equipment downtime, build the front line of defense in the factory. Reduce labor inspection costs, extend equipment life, and create the best benefits for production management!

The Main Function

Data visualization

Device status at a glance, clearly visible control panel.

AI PHM of rotating equipment

Designed for the diagnosis of rotating equipment, effectively prolonging the service life of the equipment.

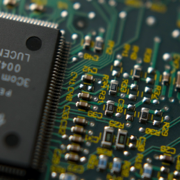

AIFS/AI.AOI for DIP PCB Solder Inspection

By deploying PCBA AI.AOI model and AIFS system, the customer has an on-premise AI.AOI solution, which allow them to label data on premises for model retraining and optimization, as well as remote deployment.

The Main Function

Visualization management panel

The pre-trained model for PCB solder spot defect detection can quickly grasp the current detection situation through the management panel, which can save time and effort.

AI automatic optical inspection system architecture

Four steps to achieve accurate detection: taking photos → DIP AI.AOI defect detection → re-judgment labeling and repair → automatic model retraining

AIFS/PCBA AI.AOI import benefits

High detection rate, low false positive rate, more efficient with AI.

WISE-AIFS Service Structure

Focused Industrie

Electronic components

Mechanical equipment

Textile industry

Metal manufacturing

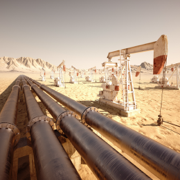

Oil and coal products