Smart Maintenance for reliable machines

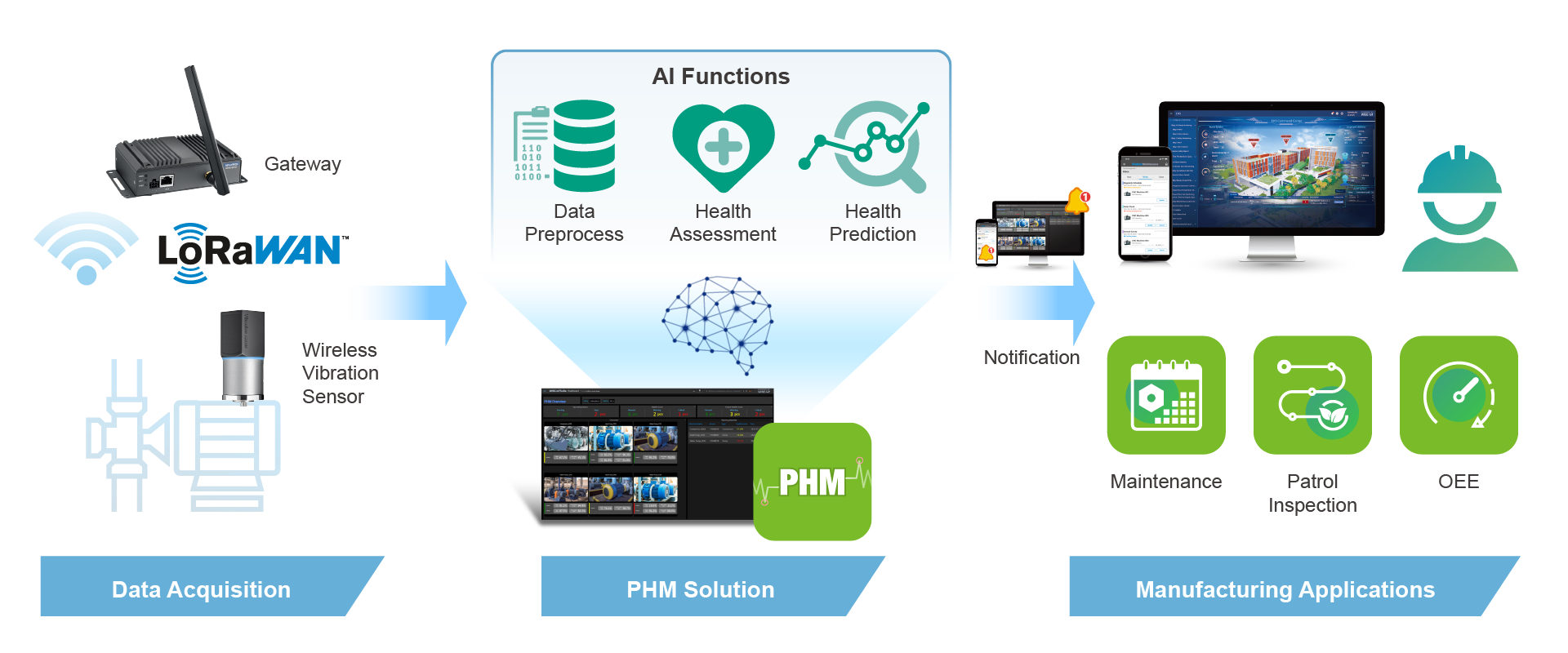

Smart Maintenance Solution with PHM enables early detection of machine anomalies and predicts health status, empowering proactive decision-making. By optimizing maintenance schedules, it ensures efficient machine management and enhances operational reliability.

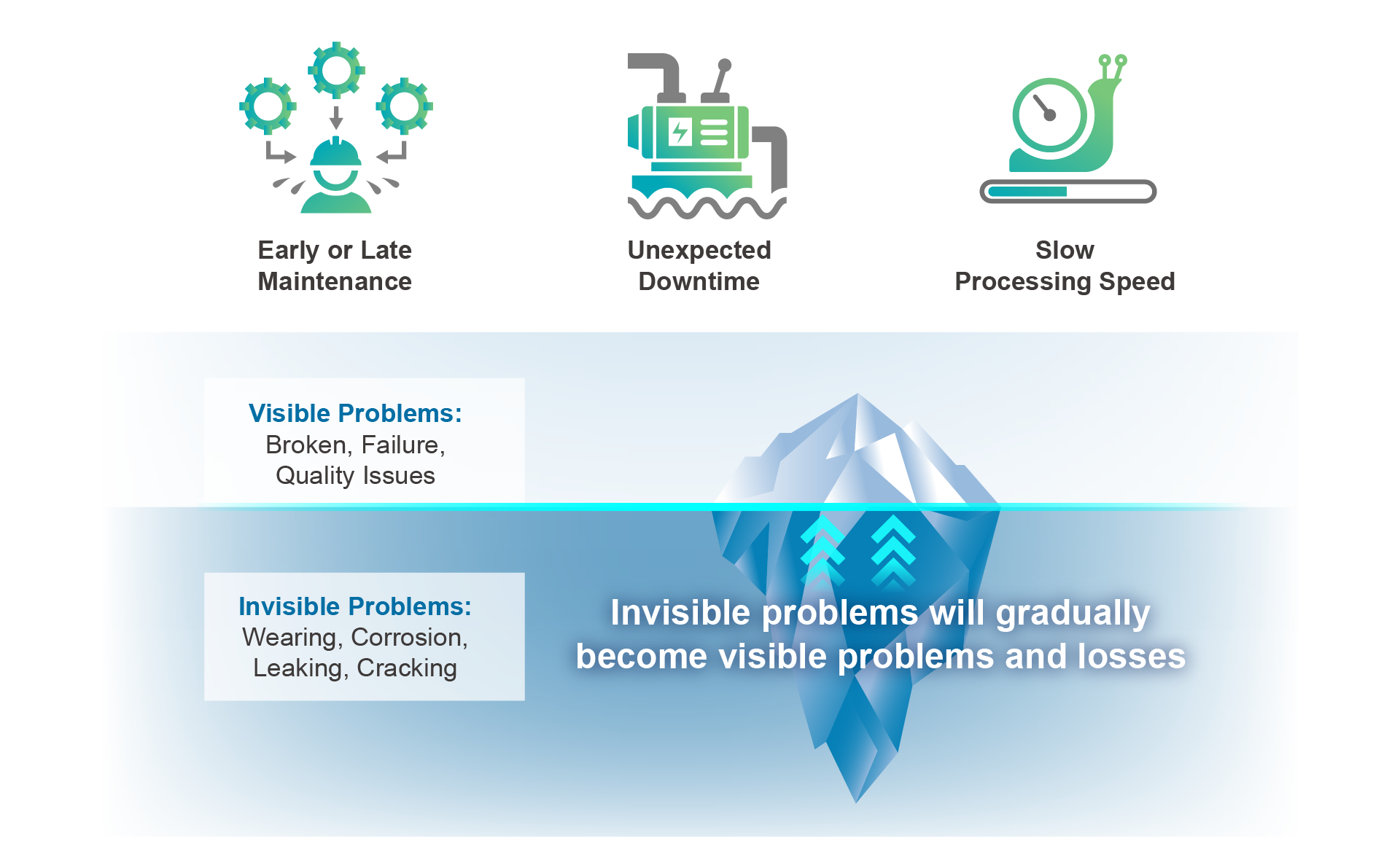

What We Face

Functions of Smart Maintenance

Health Monitoring and Prediction

Operation & Maintenance

AI Analytics

Remote Maintenance

Smart Maintenance System Diagram

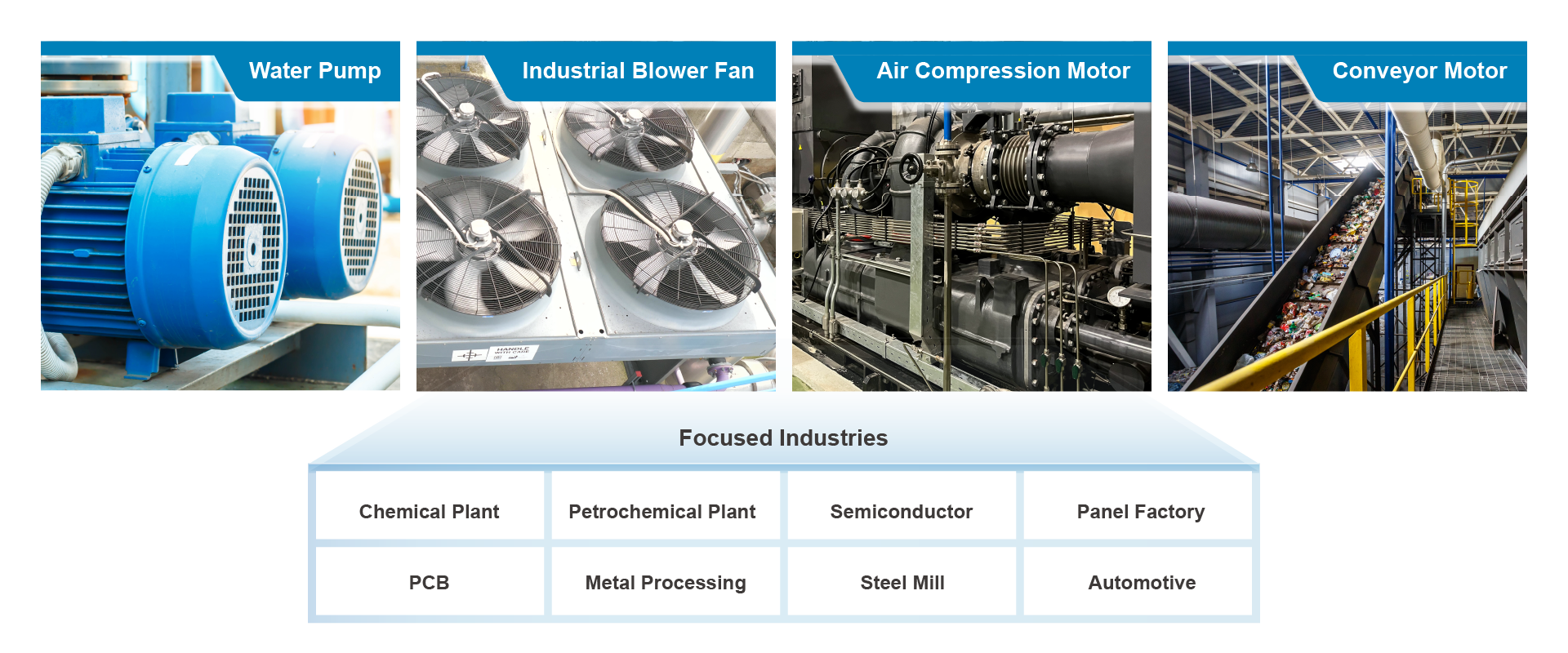

Application Scenarios

Prevent Downtime for Rotating Machine in the Petrochemical Industry

Production and safety risks due to inaccurate machine maintenance are key concerns of the petrochemical industry. Advantech iFactory develops a PHM predictive maintenance solution

PHM Solution Ready Package

- WISE-2410 3-axis vibration sensor

- WISE-6610 LoRaWAN gateway

- PHM I.App license

- Cloud with a 1-year subscription and On-Premise with One-time purchase version available

Production Line Management - Predictive Maintenance Package

- WISE-2410 3-axis vibration sensor

- WISE-6610 LoRaWAN gateway

- PHM, Maintenance, and OEE I.App licenses

- Cloud with a 1-year subscription and On-Premise with One-time purchase version available

Facility Management - Predictive Maintenance Package

- WISE-2410 3-axis vibration sensor

- WISE-6610 LoRaWAN gateway

- PHM, Patrol Inspection, and Utility Manager I.App licenses

- Cloud with a 1-year subscription and On-Premise with One-time purchase version available

Industrial Apps Information

PHM App

- Prognostics and Health Management (PHM) solution offers real-time data collection and analysis for early fault diagnosis, health prediction, and maintenance management in intelligent factories.

OEE App

- The OEE (Overall Equipment Efficiency management) App monitors the real-time status of equipment and presents only the most important information such as production quality and ratios through data acquisition and dashboard presentation.

Maintenance App

- An easy-to-use tool to speed up the visualization of all machine status and health conditions, which reduces unplanned downtime and equipment failures.

Patrol Inspection App

- Enables users to safeguard, view, and carry out patrol tasks assigned with our app.

Edge Devices Information

LoRaWAN Wireless Sensing Solutions

LoRaWAN Wireless Sensing SolutionsEmpowers users to control and manage the motor-powered mechanical equipment applications in remote areas and harsh environments.

Edge-Solution-Ready Package

Edge-Solution-Ready PackageHigh-performance, ready-to-run data acquisition, dashboard, and preinstalled software for real-time monitoring and PHM/OEE/Maintenance.

Edge Device with Touch Panel

Edge Device with Touch PanelWith the built-in touchscreen, abnormalities can be reported without the need for additional management and cost associated with a touch device.