Smart Manufacturing and Digital Transformation

Utilize IoT and Azure OpenAI for production efficiency and real-time insights to jumpstart Industry 4.0.

Manage Your Manufacturing & Equipment Efficiency with Azure OpenAI Service

By leveraging Azure OpenAI services, you can utilize IoT data to enhance productivity and OEE in your manufacturing operations. This allows for real-time insights into the status of critical production equipment and work order progression, jumpstarting your digital transformation towards Industry 4.0 and beyond.

Manage Your Manufacturing & Equipment Efficiency with Azure OpenAI Service

By leveraging Azure OpenAI services, you can utilize IoT data to enhance productivity and OEE in your manufacturing operations. This allows for real-time insights into the status of critical production equipment and work order progression, jumpstarting your digital transformation towards Industry 4.0 and beyond.

FEATURES

- 01

Real-time Equipment Monitoring

Track machine statuses and efficiency in real-time to maximize utilization.

- 02

Event Reporting

One-click reporting for employees to request assistance for anomalies and quickly return to normal production.

- 03

Transparent Progress

Update work order progress in real time from equipment data and IoT interfaces.

- 04

Digital Work Instructions

Guide employees with interactive instructions to reduce training time and improve production quality.

- 05

Master Data

Setup shared definitions of manufacturing resources for consistent management of manufacturing operations.

- 06

Visualized Insights

Ready to use dashboard templates to enable data driven decisions.

• Intelligent Maintenance to Increase Factory OEE

By using Azure OpenAI technology for intelligent maintenance, important support is provided to quickly resolve faults, reducing downtime of production lines. This allows manufacturers to maximize throughput and Overall Equipment Effectiveness (OEE) to maximize their production output.

1. Accelerate Repair Process: Fast fault diagnosis and repair with Azure OpenAI and WISE-iFactory.

2. Improve Accuracy: Accurate fault finding with experience and quick info search.

3. Simplify Process: Maintenance engineers solve problems faster with Speech to Text, WISE-iFactory solution and Azure OpenAI.

4. Enhance Equipment Efficiency (OEE): Quickly resolve equipment abnormalities to boost OEE.

• Intelligent Maintenance to Increase Factory OEE

By using Azure OpenAI technology for intelligent maintenance, important support is provided to quickly resolve faults, reducing downtime of production lines. This allows manufacturers to maximize throughput and Overall Equipment Effectiveness (OEE) to maximize their production output.

• Quickly Solving Production Line Abnormalities

By combining WISE-iFactory and Azure OpenAI, operators can quickly identify and resolve abnormal problems, increasing production efficiency and reducing delays. iFactory/Intelligent All-in-One Event Reporting, semantic learning from OpenAI and production parameter/process guide from WISE-iFactory provide optimized assistance, enabling proper arrangements and operations to ensure smooth operation of the production line.

1. Quickly Solve Abnormal Problems: With Intelligent All-in-One Event Reporting, faster analysis and judgment with WISE-iFactory and Azure OpenAI.

2. Increase Production Efficiency: By using semantic learning from Azure OpenAI to identify problems and obtain the fastest switchable work order.

3. Optimize Operation: With guide from WISE-iFactory for necessary arrangements and operations.

• Quickly Solving Production Line Abnormalities

By combining WISE-iFactory and Azure OpenAI, operators can quickly identify and resolve abnormal problems, increasing production efficiency and reducing delays. iFactory/Intelligent All-in-One Event Reporting, semantic learning from OpenAI and production parameter/process guide from WISE-iFactory provide optimized assistance, enabling proper arrangements and operations to ensure smooth operation of the production line.

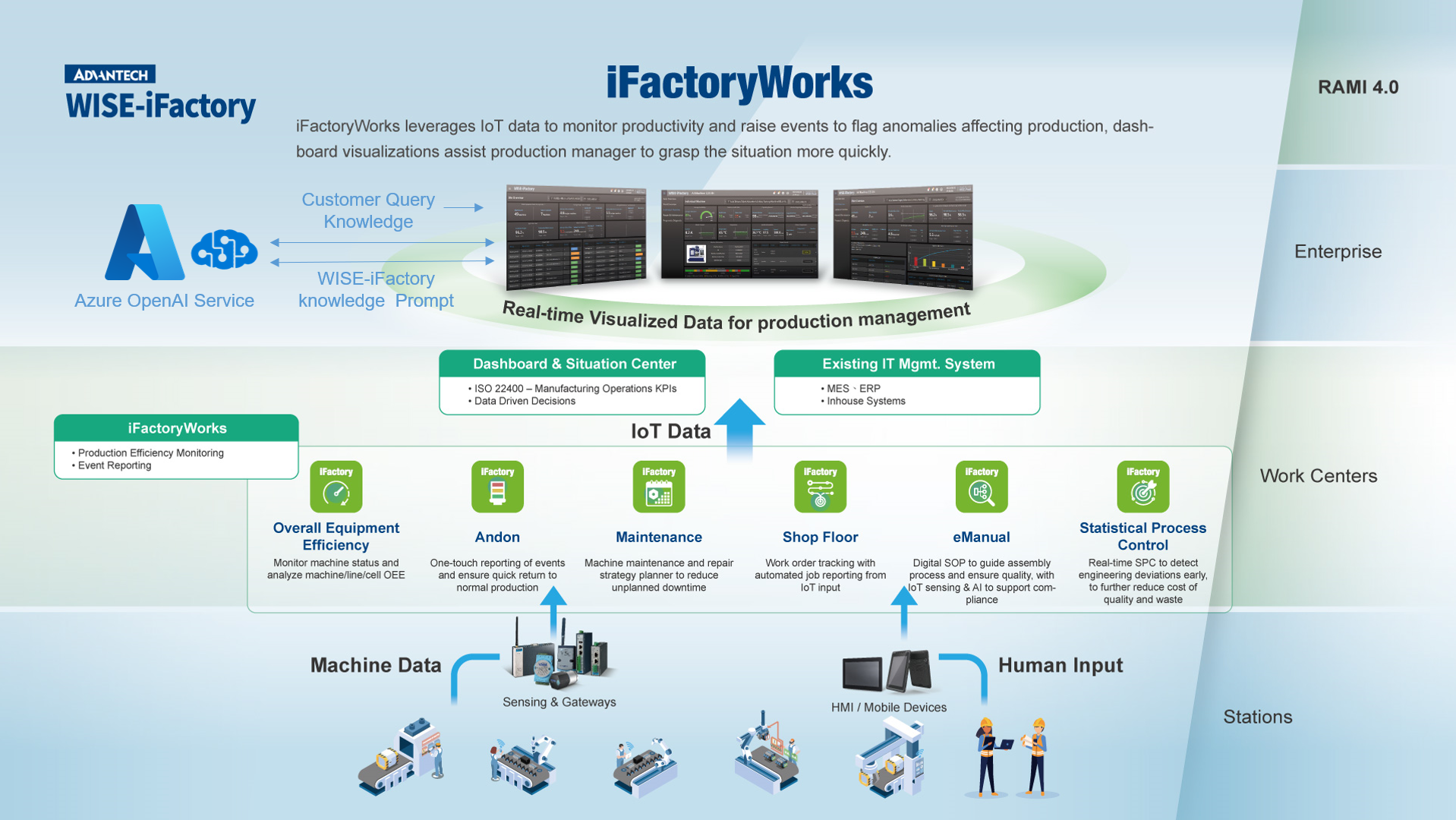

iFactoryWorks Architecture

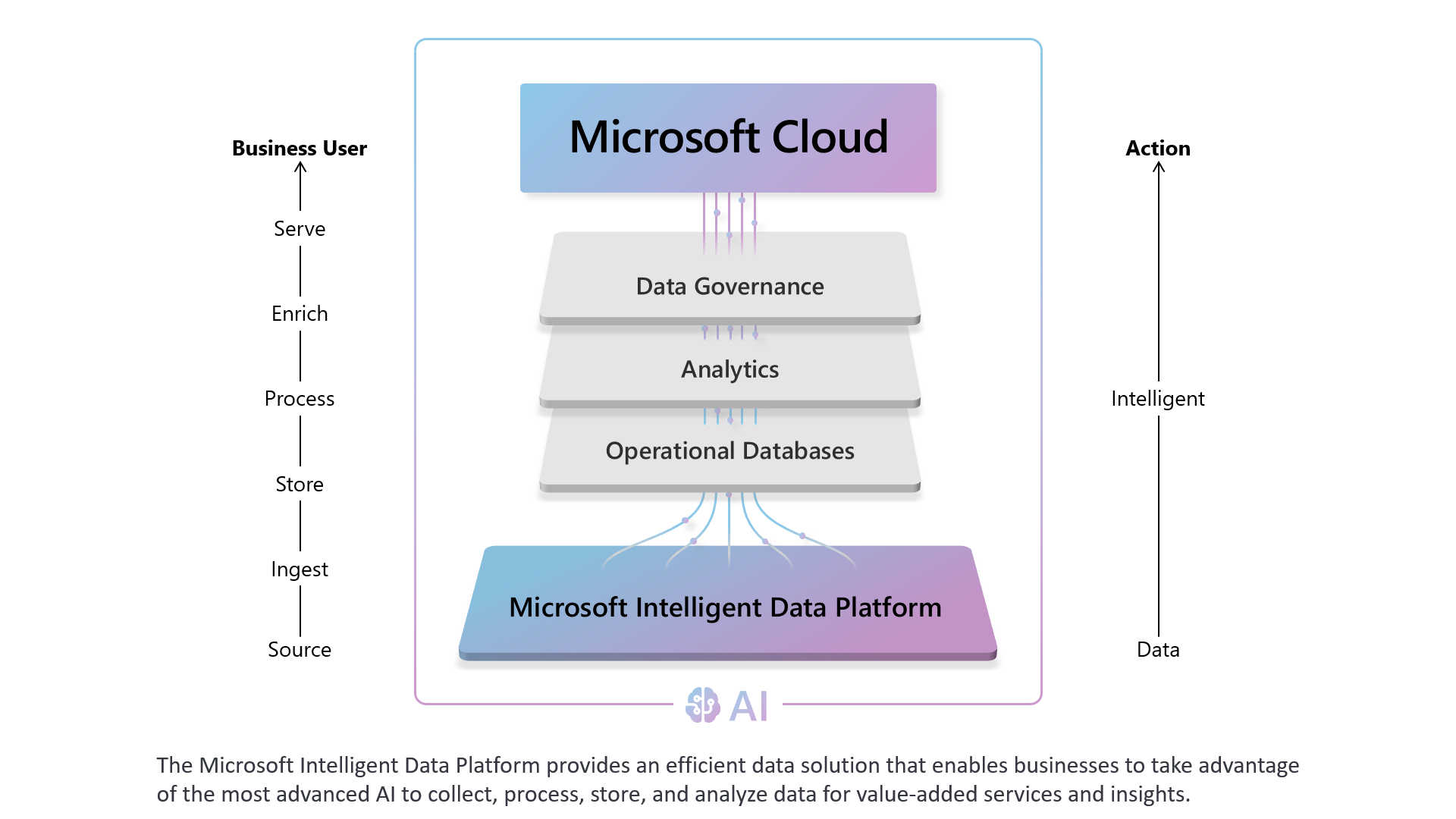

Microsoft Cloud to AI

Why do you need iFactoryWorks? - Enhancing Manufacturing OEE with iFactoryWorks Solution Suite

In the digital transformation journey of an enterprise, automation is often the first step taken to increase efficiency and productivity. However, despite its potential benefits, the implementation of automation can sometimes lead to unforeseen challenges and issues that negatively impact production processes. To address these challenges, enterprises are increasingly turning to automation Overall Equipment Effectiveness (OEE) monitoring and production optimization strategies. OEE monitoring provides real-time insight into the performance of manufacturing equipment, allowing enterprises to clearly visualize the full range of equipment and their status.

Why do you need iFactoryWorks? - Enhancing Manufacturing OEE with iFactoryWorks Solution Suite

In the digital transformation journey of an enterprise, automation is often the first step taken to increase efficiency and productivity. However, despite its potential benefits, the implementation of automation can sometimes lead to unforeseen challenges and issues that negatively impact production processes. To address these challenges, enterprises are increasingly turning to automation Overall Equipment Effectiveness (OEE) monitoring and production optimization strategies. OEE monitoring provides real-time insight into the performance of manufacturing equipment, allowing enterprises to clearly visualize the full range of equipment and their status.