iFactory for PCB Industry

Industry 4.0 brings a new perspective of PCB manufacturing

Compared with the previous industrial revolution, what are the characteristics of iFactory @ PCB Industry?

Real-time monitoring and management of edge equipment and system operation status, including equipment supervision and diagnosis, water quality and discharge, processing unit efficiency and abnormal alarm push broadcast, in order to achieve cost reduction and efficiency increase.

Compared with the previous industrial revolution, what are the characteristics of iFactory @ PCB Industry?

Real-time monitoring and management of edge equipment and system operation status, including equipment supervision and diagnosis, water quality and discharge, processing unit efficiency and abnormal alarm push broadcast, in order to achieve cost reduction and efficiency increase.

Challenges of the PCB industry management

- 01

Complex Process

- Compared with other industries, there are more process stages, and both dry and wet processes are involved.

- Low efficiency due to lack of traceability to manage complex PCB manufacturing processes.

- Lack of parameter management in the mass production process, relies on personnel selection.

- Low production management transparency.

- 02

Various Equipment Types

- Various types of PCB equipment (exposure/drilling/cutting/plating etc.), numerous equipment brands, difficult data collection.

- Manual maintenance and equipment instability leads to inconsistent product quality.

- Equipment maintenance process is complicated and not well planned, which leads to a reduction in production time.

- 03

Many Industrial Safety Incidents

- Because the factory lacks real-time monitoring and alarm systems, its ability to respond to a fire is low.

- Improper management of wastewater/exhaust gas can easily cause environmental pollution and result in fines, and severely lead to production shutdown.

- Equipment energy (water/electricity/oil/gas) information is not transparent, leading to higher production costs.

- 04

Tier one customer request data of operation and defection

- PCB manufacturers are facing increasing pressure because they are required to provide more and more detailed data of each finished PCB unit produced in their workshops.

- Customers can use the finest data granularity in the entire supply chain to quickly identify, track, and eliminate PCB defects.

iFactory PCB Industry Digital Operation Center

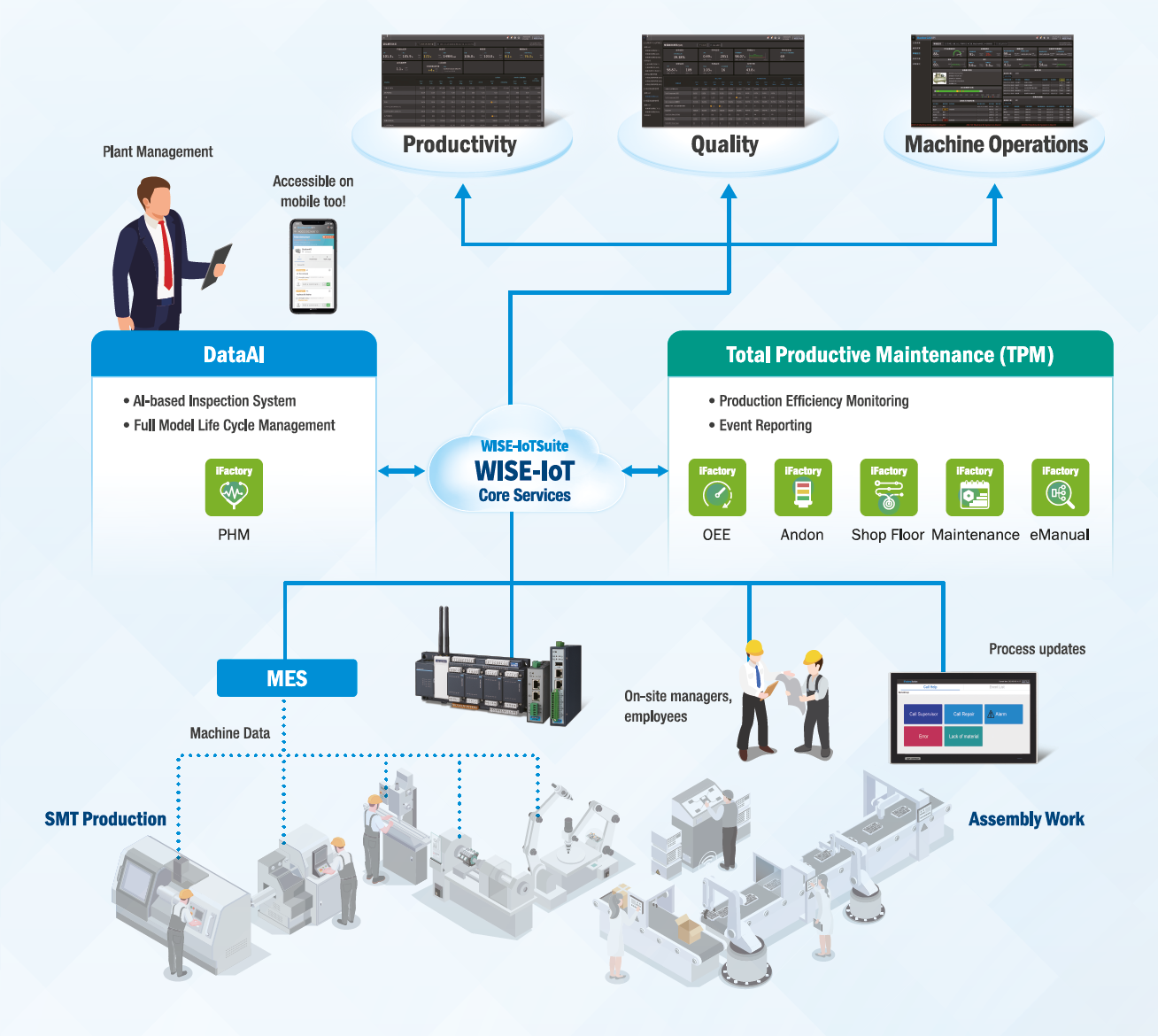

iFactory Solution suite @PCB industry can help PCB manufacturers to extract the valuable data they need faster, and accurately from measuring and monitoring the PCB board manufacturing process in different production stages, so that managers can make more informed decisions.

Advantages

- 01

Growth-Oriented

- 02

Flexibility & Agility

- 03

Technology-Driven

- 04

Innovation

I.App of the Solution Suite

DES Aqua Monitoring

Development-Etching-Stripping (DES) is a PCB manufacturing process of the inner and outer layers, which require different types of module arrangements. A typical inner layer line begins with a development process, which usually removes the unexposed resist. In the etching module, the obtained bare copper is sprayed with an acid etching solution, and then etched down to the substrate. Aqua is a special equipment for controlling the chemical stability in order to reduce the risk of defects. DES I.App is for monitoring of the process by collecting sensor inputs.

Water Treatment Monitoring

For wastewater and drainage, we can visually check equipment operations data, but it is difficult to get operations status in real time. In order to establish accurate and credible items such as (PH, COD, ammonia nitrogen value, total copper, flow value, conductivity), providing credible intelligent early warning information is necessary. Automatically collecting equipment data in real time, and establishing a central control platform query interface allows users to control the real-time water information, and set alarm limits. If the data exceeds the limit, buzzer alarms and reminders will be carried out automatically.

Oven Process

Ovens are controlled based on the internal temperature values through the internal sensors, through the control system. The hot air circulation heating method of the industrial oven has better gas flow to speed up the drying speed of the materials in the industrial oven. After ink printing, welding, or protective paint, the semi-finished products need to be sent to the oven for drying at an appropriate time and temperature. Oven I.App is used to effectively monitor actual oven temperature and to avoid improper control.

Statistical Process Control

Predict abnormal trends of the production process: Take timely measures to eliminate abnormalities and restore the stability of the process. Apply statistical analysis technology to monitor the production of automated equipment in real time. Data-based distinguishing random fluctuations and abnormal fluctuations of product quality in the production process.

System Architectures of PCB industry management

Co-Creation with DFSI

Industrial IoT (IIoT) involves integrating big data, cloud, and AI applications. To embrace this trend, Advantech is collaborating with domain-focused system integrators (DFSIs) to develop industrial apps (I.Apps).