Industry 4.0 Drives Smart Manufacturing Upgrades

Industry 4.0 technology brings process optimization to factories. Through cloud monitoring combined with sensors and equipment analysis, critical components such as electric motors can achieve real-time monitoring and predictive maintenance, quickly identifying efficiency and failure patterns. This technology helps factories maintain high motor efficiency, reduce maintenance costs, avoid expensive downtime expenses, and comprehensively improve equipment productivity and operational efficiency, providing strong support for manufacturing digital transformation.

Challenges in the Electrical Machinery Industry

- 01

Workforce Transformation

Due to market competition, companies should shorten lead times and reduce operational costs to quickly respond to customer demands. Improving employee capabilities can achieve these goals. Employee training and expectations have changed dramatically in recent years, making it increasingly difficult to hire suitable employees with relevant technical experience.

- 02

Environmental Safety

Electrical accidents are usually caused by unsafe equipment, unsafe environments, or unsafe work practices. Timely maintenance can prevent accidents from occurring. Wherever electricity is involved, there are inherent dangers, including fire, personal injury, and electric shock.

- 03

Incremental Technological Change

The electrical machinery industry needs smarter equipment to solve all problems. The market is trying to reduce energy consumption, improve control and automation, provide pre-programmed functions for many micro-decisions that affect machinery, and provide critical control components for industrial equipment. When operators press buttons, equipment will adjust and respond effectively based on intelligent control and monitoring sensors.

- 04

Costly Human Error

Assembling electrical machinery products is highly complex, and many factories still primarily use manual processes. They face many challenges during assembly, with low flexibility and high error risk. The electrical machinery industry must ensure that products after shipment have the highest operational reliability, reduce downtime, and continuously improve operational safety and standards.

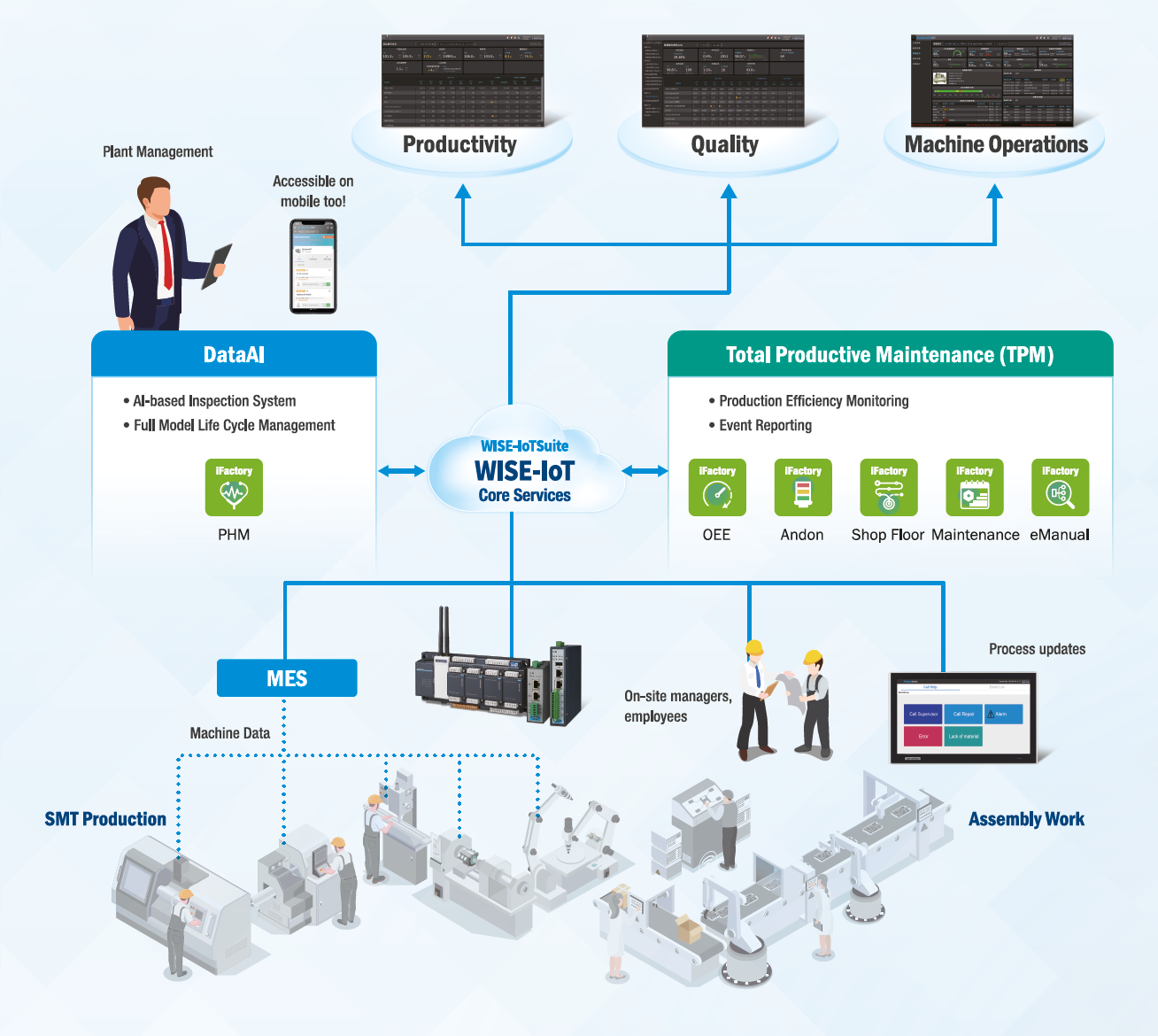

Electrical Machinery Industry iFactory

The Electrical Machinery Industry iFactory solution suite demonstrates the value that digital acceleration can bring to the industry. iFactory technology provides enterprises with the data and insights needed to strengthen digital industries in real-time.

Advantages

- 01

Process Optimization

- 02

Real-time IoT Monitoring and Tracking

- 03

Improved Product Design and Reliability

- 04

Better Safety and Environmental Protection

Solution Suite I.Apps

Preventive Maintenance System

Preventive maintenance is an important part of facility management. PMS can avoid downtime and prevent component failures, helping to improve efficiency. Use PMS analysis results to plan maintenance schedules to reduce the probability of asset failures.

Overall Equipment Effectiveness (OEE)

Visual monitoring of OEE indicators and KPIs across the entire factory through data acquisition, integration, and machine utilization analysis. Easily achieve smart factory production efficiency management, improve productivity, review and analyze major losses, enhance equipment utilization, and effectively increase production capacity.

Shop Floor

A manufacturing management system for real-time production tracking, scheduling, and work order or operation status reporting, effectively improving supervisor progress control.

Electrical Machinery Industry Management System Architecture

DFSI Co-creation Partners

Industrial IoT (IIoT) involves integrating big data, cloud, and AI applications. To align with this trend, Advantech collaborates with domain-focused system integrators (DFSI) to develop industrial applications (I.Apps).