Breaking Outdated Processes to Enhance Digital Workflows

The metal processing industry faces major transformation challenges due to diverse orders and high-precision demands. With Industry 4.0, smart factories integrating IoT, robotics, and big data enable open, modular, and connected systems. Leveraging real-time data, they achieve flexible production, higher efficiency, and better visibility—empowering quick responses to market and technical demands.

Accelerate Industry 5.0 Transformation

Advantech iFactory enhances production efficiency and prioritizes Environment, Health, and Safety (EHS) to safeguard employees, the public, and the environment. To maximize manufacturing efficiency, iFactory leverages the power of AI analytics and Azure OpenAI services for real-time business intelligence and enhanced productivity. Seamlessly integrating these elements, iFactory propels manufacturers forward in their industrial digital transformation.

Recommended Apps

Overall Equipment Effectiveness (OEE)

Visualized monitoring of OEE indicators and KPIs of the whole plant through data acquisition, aggregation, and machine utilization analysis. Smart factory production efficiency management can be easily realized to increase productivity, review and analysis of major losses, improve equipment utilization, and effectively increase production capacity.

Facility Management & Sustainability (FMS)

FMS tracks and monitor whole plants in real time for energy saving, carbon reduction, environmental protection and safety. Energy consumption of the whole plant can identify anomalous power consumption with warning alarms to reduce cost and improve efficiency.

Event Center

Event and alarm management with notification and messaging services to enable critical events to be promptly identified and addressed. It also supports warning conditions for different trigger levels of alarm to notify key people and prevent production bottlenecks.

Command Center

Set up a war-room or command center to monitor the full plant in real-time. Built-in dashboard template with customized plug-in for ease-to use, can be managed and adjusted immediately after data integration. Standardized general functions, providing front and back-end overview entry.

Focused Industries

PCB

Optimizes the overall process through advanced analysis to identify problem areas in production.

Pulp & Papers

Digital transformation of machines and equipment for the pulp and paper industry.

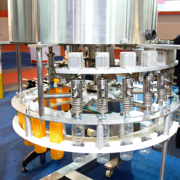

Food & Beverage

OEE (Overall Equipment Effectiveness) for manufacturers in the food and beverage industries without sacrificing quality.